Ishikawa Diagram Untools

Solved Ishikawa Diagram Example: Step by Step. For this solved example of Ishikawa diagram we are going to use a bench. Step 1: The problem detected by the bank's quality control department is: Very high waiting time for the bank's users.. Step 2: Brainstorming, it has been decided to circle the problem from the categories that have been affecting the bank's service the most.

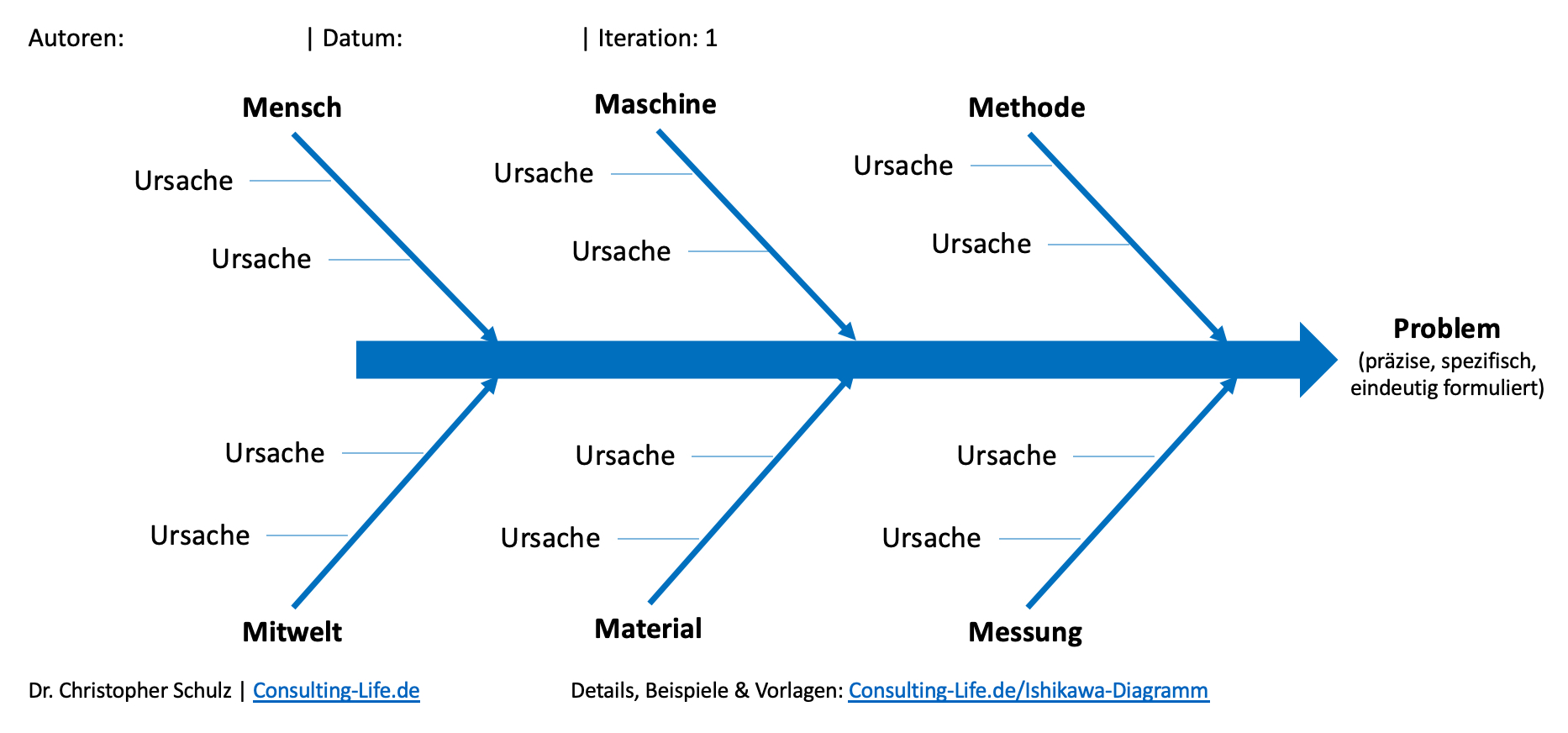

Ishikawa Diagramm Einsatz & Vorlagen ConsultingLIFE.de

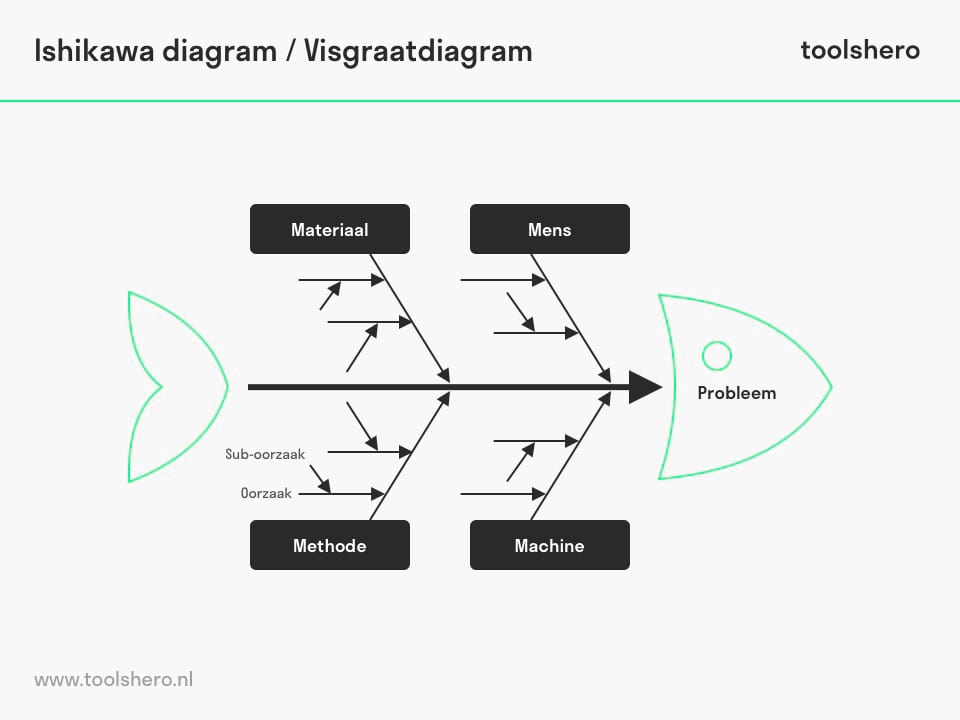

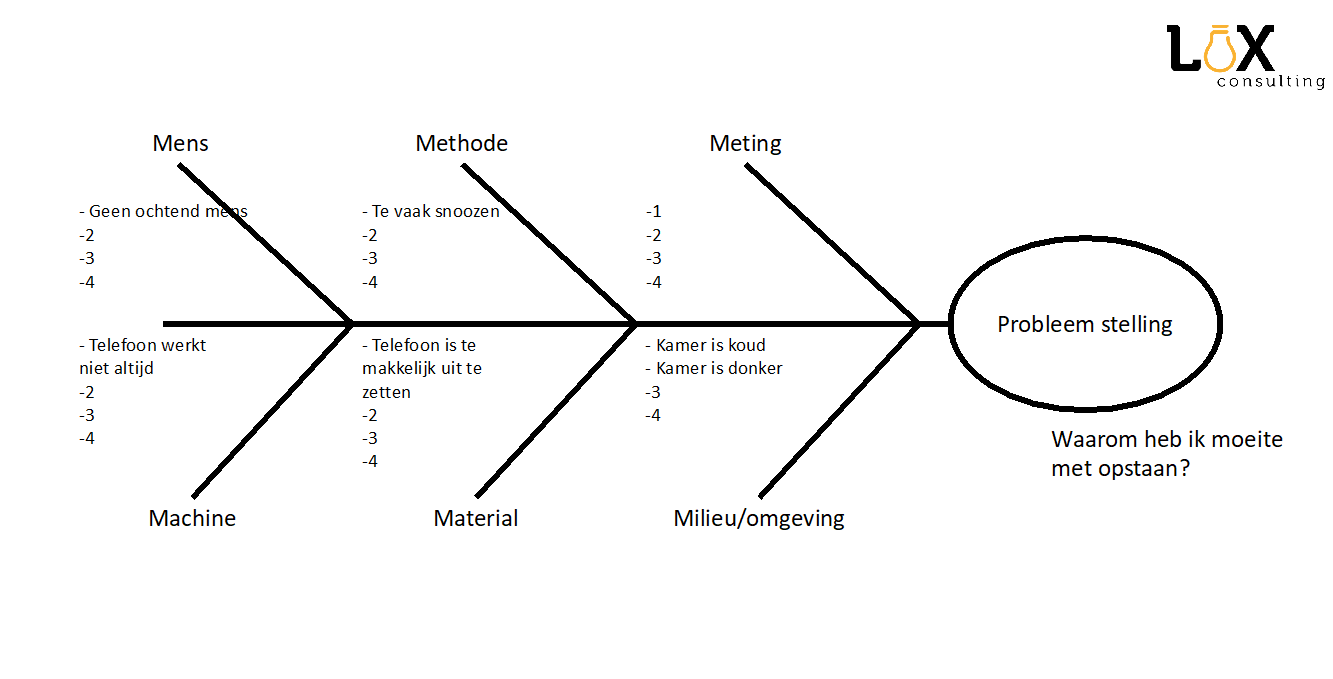

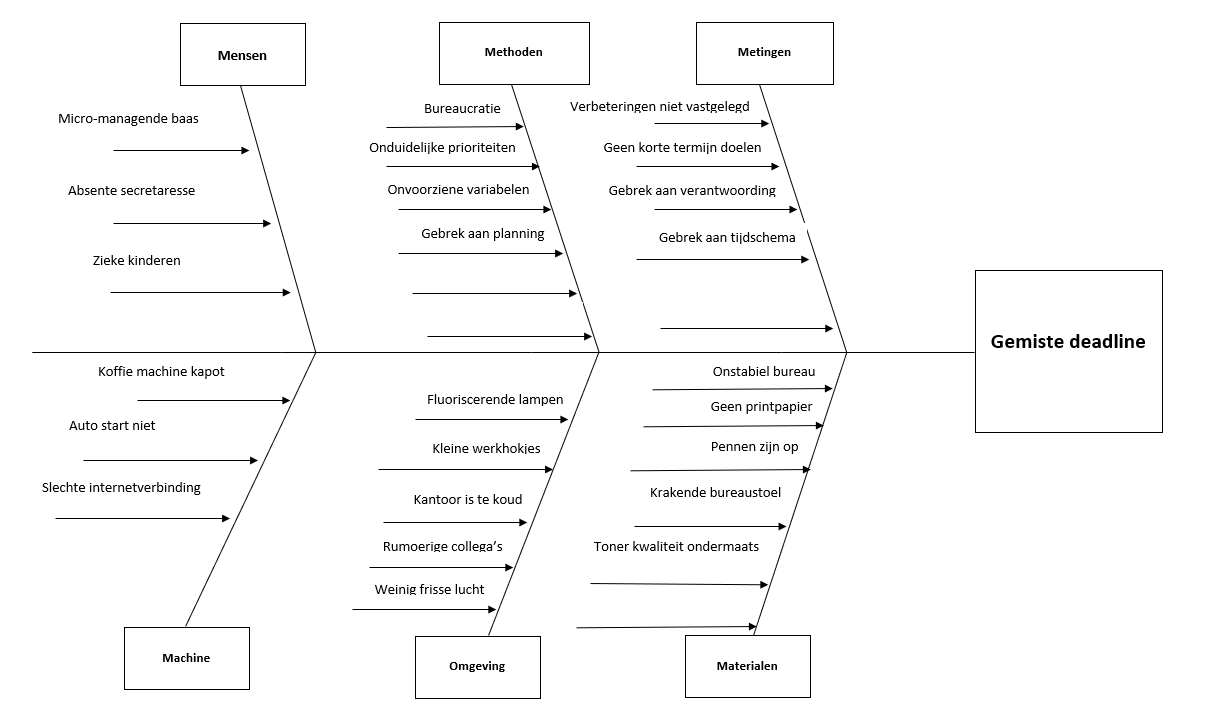

Een Ishikawa-diagram, ook wel visgraatdiagram of oorzaak-en-gevolgdiagram genoemd, is een visuele weergave die wordt gebruikt om de mogelijke oorzaken van een specifiek probleem of effect te analyseren en weer te geven.

Ishikawa Methode

Hoe maak je een Ishikiwa diagram? De methode volgt vier stappen. Als eerste moet er overeenstemming zijn over de probleemdefinitie (Effect). Dit statement wordt opgeschreven aan de rechterkant van een flipchart of white board. In de volgende stap (2) wordt de basis van het diagram opgezet (de ruggengraat).

Ishikawa diagram maken de uitleg Toolshero

Hence, the Ishikawa diagram (Fig. 9.6) is a "living" diagram that can be continually updated to reflect ongoing research findings. Simon has progressed well in cognitive behavioural therapy. He is more cheerful and well aware of the value of life and he believes that suicidal behaviour is silly because that behaviour will hurt his family and loved ones, and death does not solve any problem.

Ishikawa diagram Wikipedia

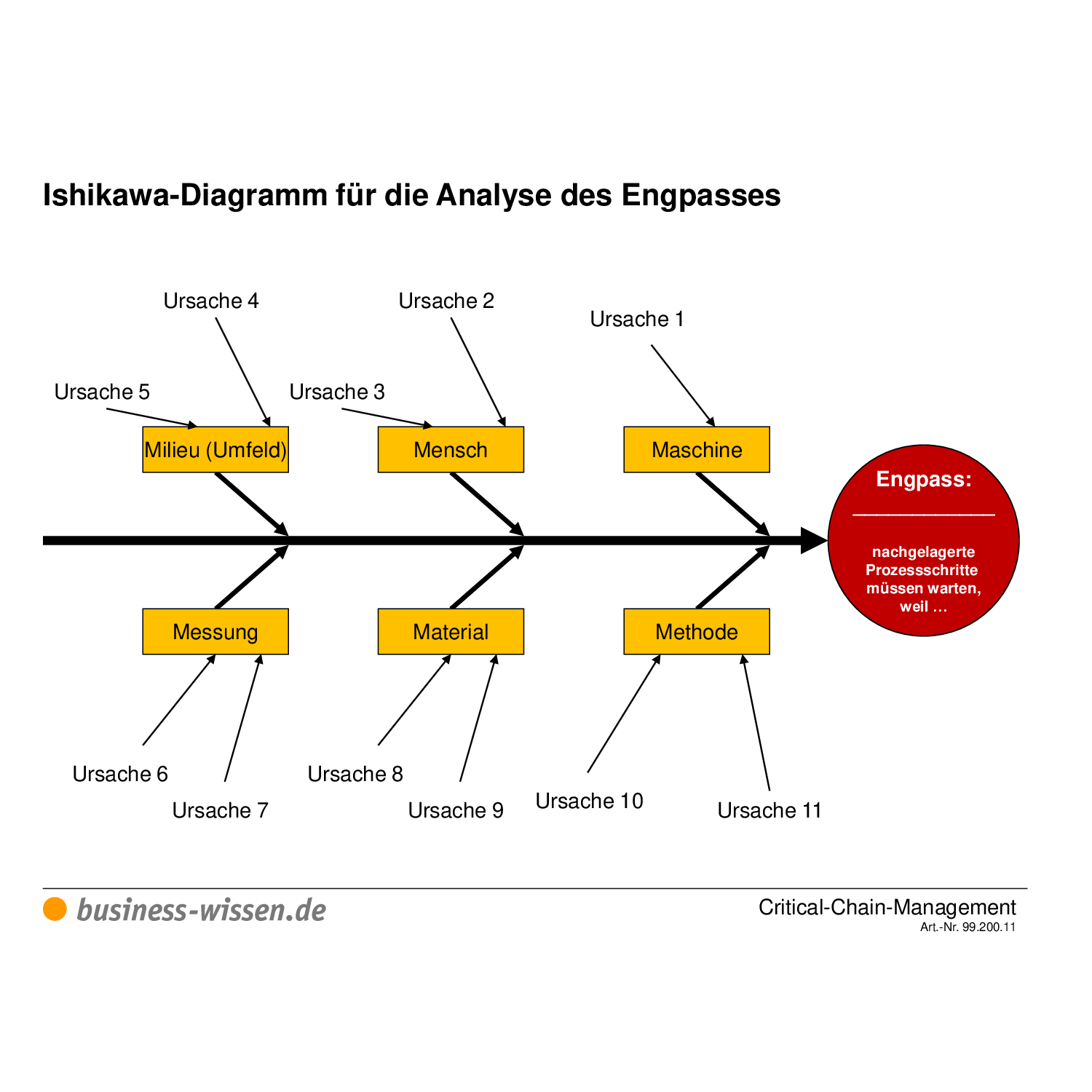

An ishikawa diagram is a visualization of the causes of a failure grouped into categories. This is used for problem analysis, root cause analysis and quality improvement to identify factors that have contributed to a problem. Ishikawa diagrams look like a fishbone with a head labeled with a problem and bones that represent different categories of root cause.

Ishikawa diagram on the example of the quality of production of bakery... Download Scientific

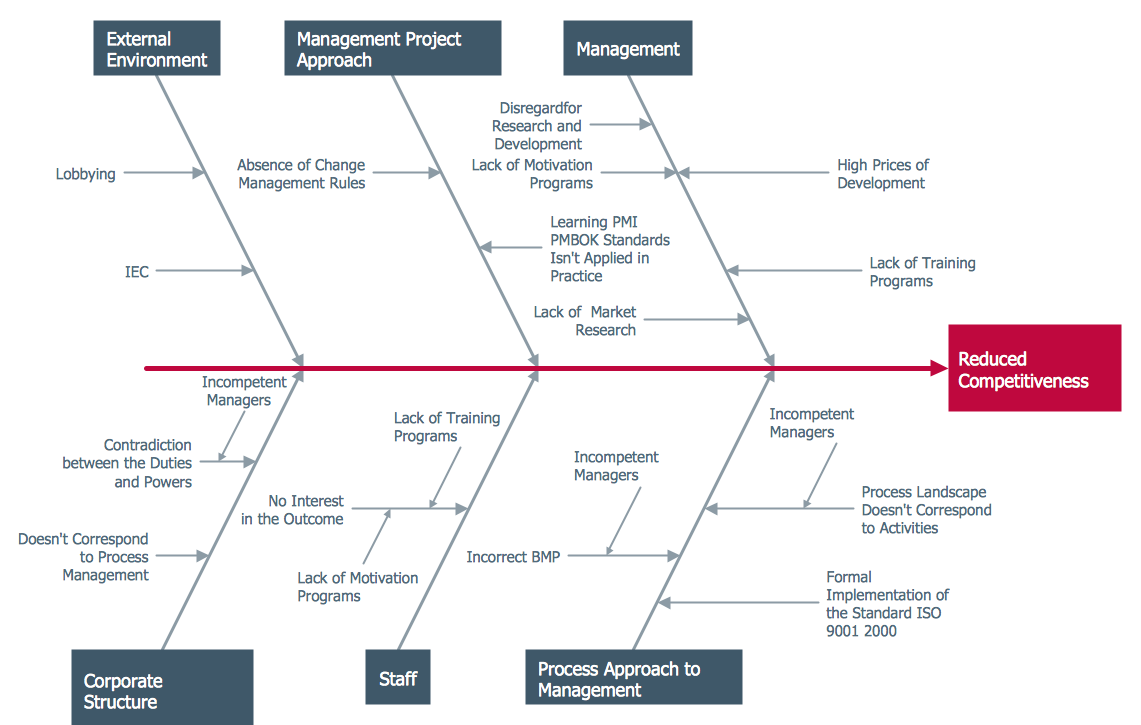

A new model of Ishikawa diagram for quality assessment CC BY 3.0 Authors: Liliana Luca Constantin Brâncusi University The paper presents the results of a study concerning the use of the.

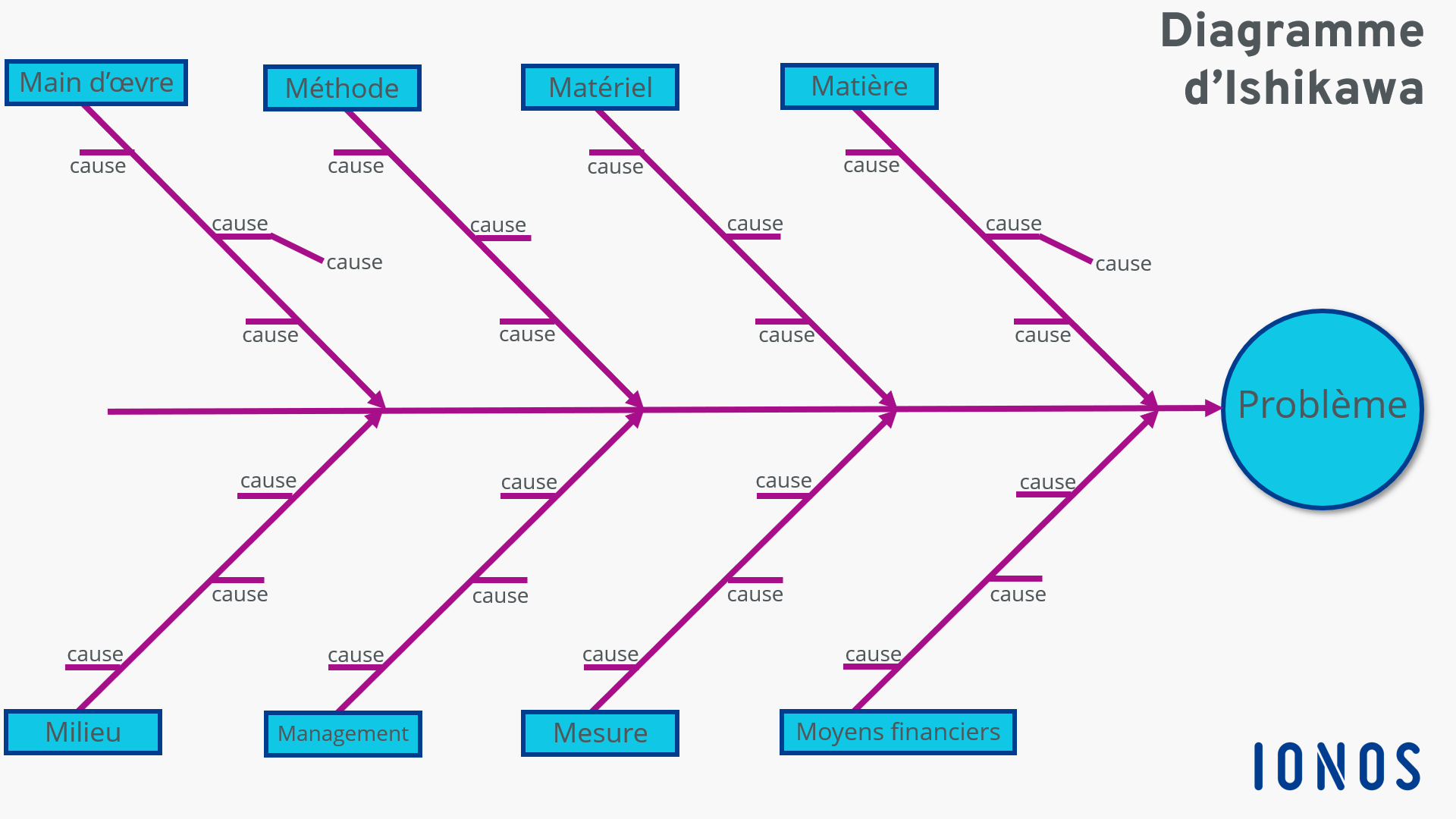

Diagramme d’Ishikawa le diagramme de causes et effets expliqué IONOS

Make a diagram 99% of the Fortune 500 trust Lucidchart to keep teams on the same page. Get started with ishikawa diagram templates To create a ishikawa diagram in Lucidchart, click this pre-made template and edit it to suit your purposes. To edit the text, double-click it and begin typing.

Visgraat diagram (Ishikawa) projectmanagementsite

Ishikawa diagrams (also called fishbone diagrams, [1] herringbone diagrams, cause-and-effect diagrams) are causal diagrams created by Kaoru Ishikawa that show the potential causes of a specific event. [2] Common uses of the Ishikawa diagram are product design and quality defect prevention to identify potential factors causing an overall effect.

Ishikawa diagram Lux Consulting

Ishikawa diagrams, also known as Fishbone diagrams or Cause-and-effect diagrams, are essential tools in the world of quality management and problem-solving. Developed by Dr. Kaoru Ishikawa in the 1960s, these diagrams provide a visual representation of factors contributing to a specific outcome. By analyzing the various causes and effects, teams can identify root problems and.

Fishbone diagram (Ishikawa) for cause and effect analysis editable online

Ishikawa diagram, also called the Fishbone diagram, is a tool used to identify problems in a system. It shows how causes and effects are linked and helps analyze what is going wrong with systems, processes, and products. The name comes from Japanese engineer Kaoru Ishikawa who developed the method in the 1960s.

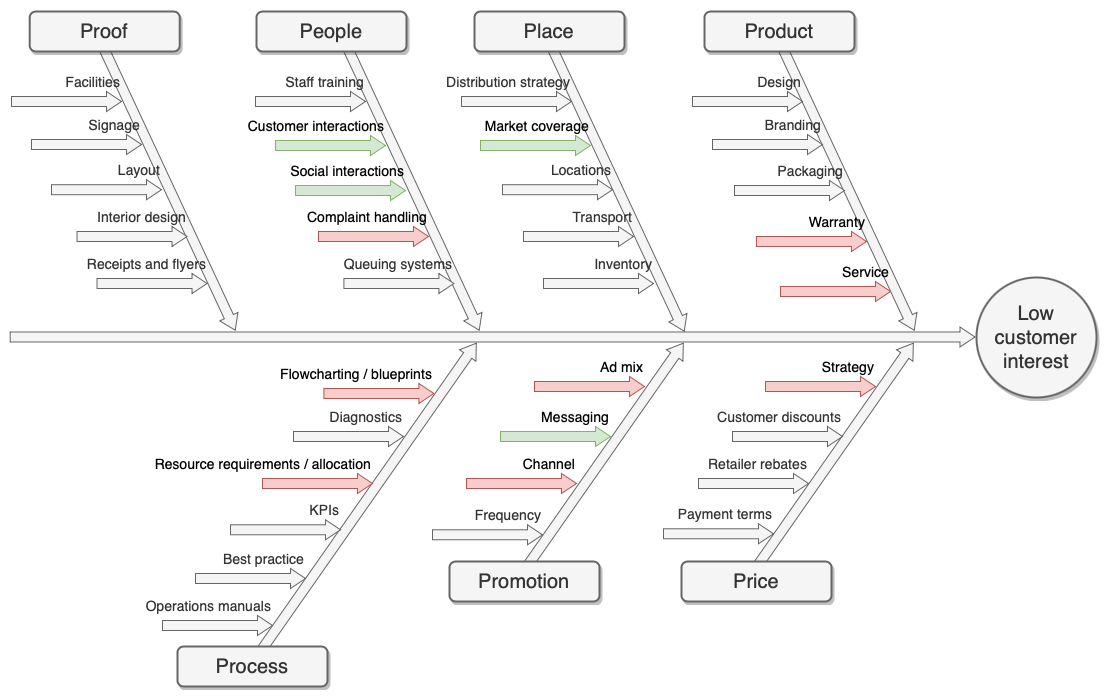

Ishikawa Diagram Template for Marketing. You can edit this template and create your own diagram

An Ishikawa diagram, also known as a fishbone diagram or cause-and-effect diagram, is a visual representation used to analyze and display the potential causes of a specific problem or effect. This diagram is named after Professor Kaoru Ishikawa, a Japanese quality control statistician, who popularized its use in the 1960s.

Ishikawa Diagram Lean Six Sigma Groep

Root cause analysis (RCA) is a way of identifying the underlying source of a process or product failure so that the right solution can be identified. RCA can progress more quickly and effectively by pairing an Ishikawa diagram with the scientific method in the form of the well-known plan-do-check-act (PDCA) cycle to empirically investigate the failure.

Blog Ishikawa diagrams for root cause analyses

An Ishikawa diagram is a diagram that shows the causes of an event and is often used in manufacturing and product development to outline the different steps in a process, demonstrate where.

Ishikawa Diagram Professional Business Diagrams

Ishikawa Diagram Hoe maak je Lean praktisch met een Ishikawa- of visgraatdiagram? De term 'praktisch' kent een paar synoniemen, zoals 'efficiënt', 'handig', 'toegepast' en 'bruikbaar'. Lean is gelukkig ook lekker praktisch, oftewel, je kunt ermee in de praktijk uit de voeten. Je kunt Lean toepassen op veel situaties, zowel op je werk als thuis.

Ishikawa Diagram Template Word

Het visgraatdiagram (ook Ishikawa-diagram genoemd) kun je gebruiken voor je probleemanalyse. Het diagram is vooral handig wanneer je moeite hebt om de probleemstelling en doelstelling goed te definiëren. Inhoudsopgave Opbouw van het visgraatmodel Voorbeeld probleemanalyse met visgraatmodel Stappenplan brainstormsessie

Ishikawadiagram Managementmodellensite

To create an Ishikawa diagram in Lucidchart, click this pre-made template and edit it to suit your purposes. This marketing-oriented chart shows potential causes of low website traffic. The spine and branches of the diagram are made of straight lines—to add more, press L and drag your mouse. To edit the text, double-click it and begin typing.